| Vacuum

Shelf Dryers |

STOKES

VACUUM INC.

|

|

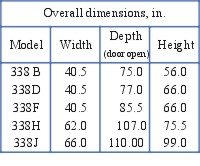

These highly engineered chambers provide safe, efficient drying

of heat and/or air

sensitive materials that require drying without agitation. Sturdy

welded external chamber reinforcement ensures maximum operating

protection and dependability under full vacuum operation. From 4sq.ft

to 270sq.ft of shelf area for material batch processing.

|

|

|

Vacuum

Condensers

For applications involving organic solvents. The use of a precondenser

with pressure control improvesrecovery and reduces pump size. Stokes

manufactures the three basic types of condensers, all designed specifically

for vacuum service.

|

Shell

and Tube-Vertical, large diameter tubes with integral Shell

and Tube-Vertical, large diameter tubes with integral

condensate receiver. Liquid cooled

Finned

Tube-High-efficiency, compact design with integral

condensate receiver. Water or refrigerant cooled Finned

Tube-High-efficiency, compact design with integral

condensate receiver. Water or refrigerant cooled

Vertical

Plate-vertical plate bundle condenses vapor to ice. Refrigerant

cooled Vertical

Plate-vertical plate bundle condenses vapor to ice. Refrigerant

cooled

Request Bulletin 490-3

|

| Pharmaceutical

Freeze Dryers |

|

|

旭豪真空科技有限公司

SHANG HAUR INDUSTRIAL CO., LTD.

台北縣土城市大安路142號

NO.142,DAH AN Road, Tu Cheng City,

TAIPEI HSIEN, TAIWAN, R.O.C.

TEL:02-8076-3000 FAX:02-8076-3300

E-MAIL:sh.vacuum@msa.hinet.net

|

|

|