Chemical Series

Dry Vacuum Pumps |

STOKES

VACUUM INC.

|

|

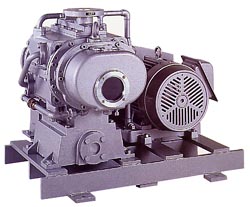

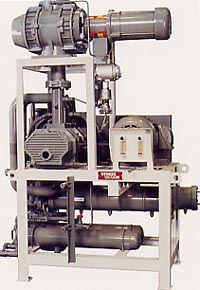

607 blower,

CD-250 dry pump.

Capacity 525 cfm at 1 torr

|

Chem-Dry pumps

use no fluids for seal-

ing, eliminating the possibility of their

contaminating your process or causing

downstream pollution. You get a purer

process and end product and save on

waste disposal, fluids, and labor.

ReqUCSt Bulletin CD1-B |

Chem-Dry

Applications

●Vacuum Distillation and Solvent

Stripping - excellent for solvent recovery

● Pharmaceutical Production -

recovery of solvents, collection of

intermediates

● Pilot Vacuum Processes - differen-

tial condensation, recovery of high-

boiling intermediates

● Flavors and Fragrances - enhanced

recovery of essential oils, terpinoids,

and complex flavor concentrates

● Medical Device Fabrication - clean,

sterilizable vacuum pump for

implantable device manufacture.

Recovery of ethylene oxide gas

sterilants

● Materials Research - pump aggres-

sive gases safely at high flows and

concentrations

● Fatty Acid Production - elimination

of water pollution and drain blockage

from ejector effluents

|

| CD

Series Dry Pump Specifications |

| Model No. |

CD-75 |

CD-120 |

CD-180 |

CD-250 |

CD-500 |

CD-750 |

| Nominal pump spd, cfm |

75 |

120 |

180 |

250 |

500 |

750 |

| Motor hp |

5 |

7.5 |

10 |

15 |

30 |

40 |

| Inlet flange, in. |

1.5 |

2 |

2.5 |

3 |

4 |

5 |

| Exhaust flange, in. |

1 |

1.25 |

1.5 |

2 |

2.5 |

3 |

|

Sizing: Stokes Vacuum Dry Pumps are staged

dry lobed mechanical pumps. They develop base

pressures to 1 torr or better and are available in a

wide range of sizes. Because the pumps are true

dry backing pumps, they can be employed with

rotary lobed blowers for more speed and lower

pressure (0.03 torr typically).

|

CD

Series Dry Pump/Blower Systems Specifications

| Model No. |

31018 |

31025 |

60725 |

60751 |

61551 |

61550 |

61552 |

61553 |

| Blower |

310 |

310 |

607 |

607 |

615 |

615 |

615 |

615 |

| Pump |

CD 180 |

CD 250 |

CD 250 |

CD 500 |

CD 500 |

CD 500 |

CD 500 |

CD 500 |

| Displacement: |

Blower, cfm |

| Pump, cfm |

|

400 |

400 |

600 |

800 |

1100 |

1300 |

1600 |

2000 |

| 211 |

305 |

305 |

583 |

583 |

583 |

583 |

583 |

| Cut-in pressure, torr |

30 |

30 |

30 |

75 |

30 |

30 |

30 |

15 |

Pressure limit for

continuous operation, torr |

30 |

30 |

30 |

75 |

20 |

20 |

20 |

15 |

| Motor: |

Blower, hp |

| Pump, hp |

|

2 |

2 |

5 |

5 |

10 |

10 |

15 |

15 |

| 10 |

15 |

15 |

30 |

30 |

30 |

30 |

30 |

| Connections: |

suction, in. |

| exhaust, in. |

|

4 |

4 |

6 |

6 |

8 |

8 |

8 |

8 |

| 1.5 |

2 |

2 |

2.5 |

2.5 |

2.5 |

2.5 |

2.5 |

Utilities

/ Water

Pump,gpm

Blower intercooler, gpm

|

4.75 |

6 |

6 |

8.75 |

8.75 |

8.75 |

8.75 |

8.75 |

| |

|

4-8 |

|

|

|

4-8 |

6-10 |

| Nitrogen, scfm |

0.2 |

0.2 |

0.2 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

| Dimensions: |

Height, in. |

| Length, in. |

| Width, in. |

|

73 |

75 |

80 |

90 |

90 |

90 |

90 |

90 |

| 57 |

63 |

63 |

65 |

65 |

65 |

65 |

65 |

| 37 |

41 |

41 |

53 |

53 |

53 |

53 |

53 |

The New Chem-Dry

Eagle Series pumps are ultra compact and need no inter-stage heat

exchangers, drain tanks, or external pipling. Plus they can run hot

or cold and handle wet acids. All models use two parallel single-piece

tri-lobe rotors, gear driven with precision bearings.

|

Chem-Dry

Eagle

Features and Benefits

●Vertical flow path - for efficient partic-

ulate handling

● Horizontal construction - for ease

of service

● Built with materials that can

withstand tough service

● Direct cooling of process gas via

the unique flow path design

● Isothermal compression

● No cold spots on the pumping

chamber wall due to direct cooling

● Small and compact

● Temperature controllable

● Constant horsepower over the

operating range

● Able to handle liquid upsets with-

out the need to reset a shear pin

● Can operate at any point on the

performance curve and handle

bursts of air |

| Eagle

Dry Pump Specifications |

| Model No. |

CDE-75 |

CDE-120 |

CDE-180 |

CDE-250 |

| Average pump spd, cfm |

70 |

106 |

166 |

236 |

| Motor hp |

5 |

7.5 |

10 |

15 |

| Inlet flange, in. |

1.5 |

2 |

2.5 |

3 |

| Exhaust flange, in. |

1 |

1.5 |

1.5 |

2 |

| Dimensions, in. (I x w x h) |

51 x 33 x 51 |

56 x 34 x 54 |

64 x 39 x 58 |

79 x 31 x 57 |

|

Request

Bulletin CDE-1

|

Eagle

Dry Pump/Blower Systems Specifications

| Model

No. |

| 306 E |

306 E |

310 E |

| 75-1 |

75-2 |

75-1 |

|

| 306 E |

310 E |

607 E |

607 E |

| 120-2 |

120-1 |

120-1 |

120-2 |

|

| 310 E |

607 E |

607 E |

| 180-1 |

180-2 |

180-1 |

|

| 310 E |

607 E |

607 E |

| 250-1 |

250-2 |

250-4 |

|

| Pump |

CDE-75 |

CDE-120 |

CDE-180 |

CDE-250 |

| Blower |

|

|

|

|

| Displacement: |

Blower, cfm |

| Pump, cfm |

|

|

|

|

|

| Cut-in

pressure, torr |

|

|

|

|

| Motor: |

Blower, cfm |

| Pump, cfm |

|

|

|

|

|

| Connections: |

suction, in. |

| exhaust, in. |

|

|

|

|

|

| Utilities

/ Water-Pump, gpm |

1.8 |

2.6 |

3.7 |

5.3 |

| Nitrogen

purge, scfm |

|

|

|

|

|

旭豪真空科技有限公司

SHANG HAUR INDUSTRIAL CO., LTD.

台北縣土城市大安路142號

NO.142,DAH AN Road, Tu Cheng City,

TAIPEI HSIEN, TAIWAN, R.O.C.

TEL:02-8076-3000 FAX:02-8076-3300

E-MAIL:sh.vacuum@msa.hinet.net

|

|

|